1. Pneumatic component: Taiwan AIRTAC

2. Program controller: Siemens, Germany

3. Man machine interface: German Siemens 7-inch color touch screen

4. Photoelectric sensor: German Leuze or domestic special sensor

5. Relay and air switch: Schneider, France

6. Motor frequency converter: Siemens, Germany

7. Conveyor belt motor: domestic brand frequency conversion speed regulation motor

8. Machine cover material: stainless steel and plexiglass

9. Materials of exposed parts: stainless steel, anodized aluminum alloy, electroplated 45 steel and plastic parts.

10.Conveyor belt: 82mm wide POM chain belt, 800mm ± 25mm above the ground

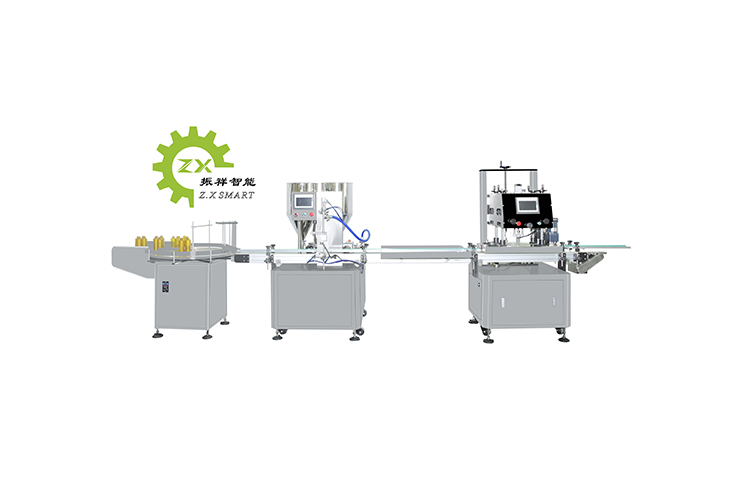

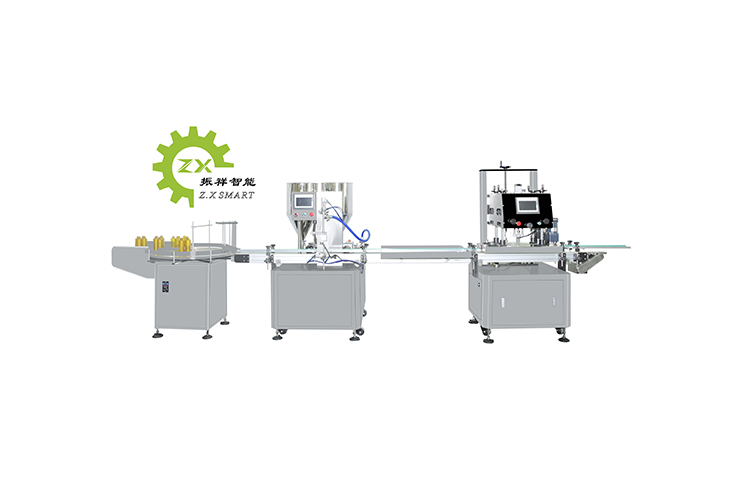

(Filling Materials As Shown In The Pictures)

(Capping Cap As Shown In The Pictures)

(Machine Details)

(Machine Details)

Working Principle:

The bottle turntable drives the product to rotate automatically. The bottle is close to the edge of the turntable under the fluctuation of the machine, and the bottle moves orderly along the edge of turntable.

Features:

1. It is applicable to the automatic transmission of round and square bottles, such as the conveyor belt connected to labeling machine, filling machine and capping machine to automatically send bottles and improve efficiency;

2. The applicable bottle range can be adjusted freely. The bottle conveying speed is 30 ~ 200 bottles / min. the speed can be adjusted to facilitate production arrangement.

Technical Parameter:

Applicable product diameter and height: φ 20mm~ φ 100mm, 20mm ~ 150mm

Weight: About 60kg

Frequency: 50Hz

Voltage: 220V

Power: 120W

Overall dimension of equipment:990(L) × 900(W) × 1040(H)mm

Working Principle:

Working Principle:

This rotor pump filling machine is composed of PLC controller,servo motor,rotor pump, hopper, filling nozzle. The machine is very suitable cream paste products with high viscosity, such as shampoo, liquid soap, honey, jam, etc. Also can be used to filling liquid products.

Features:

1. With no bottle no filling function, liquid level automatic control feeding, effectively reduce equipment failure;

2. The overall appearance is made of 304 stainless steel with a thickness of 1.2mm;

3. Filling volume and filling speed adjustment is simple, by the touch screen operation and display, beautiful appearance;

4. Trough and other liquid contact parts of the material: 304 stainless steel, food grade silicone, food grade PVC;

5. The equipment has strong compatibility, without changing parts, it can quickly adjust and replace bottles of different shapes and specifications, which can meet the production requirements of many varieties and specifications

Technical Parameter:

1. Number of filling heads: 1

2. Filling capacity: 500ml

3. Filling speed: 20-23 bottles / min (500ml bottle)

4. Filling accuracy: ± 1%

5. Material: 304/316 stainless steel

6. Program control: PLC + touch screen

7. Materials of liquid contacting parts: 316 stainless steel and PTEF

8. Air pressure: 0.6-0.8mpa

9. Power: 3.5KW/220V

10. Chute capacity: 50L (with liquid level switch).

11. Protective device: stop alarm due to lack of liquid in the liquid storage tank.

Working Principle:

Working Principle:

Automatic Servo Four Wheel Capping Machine has good compatibility for various caps. It can be applied to different bottle shaped cap of the food, pharmaceutical, cosmetic, pesticide, cosmetic and other industries. In addition, optional for caps feeding device and caps pressing device can improve productivity and reduce labor.

Features:

1.High quality steel stainless machine frame, components and shell, beautiful appearance, easy to clean, and meet the GMP requirements

2.Four wheel clamping rotation, reasonable structure, stable performance, and high working efficiency. The capping technology effectively solves the drawbacks of the traditional capping machine such as cap skidding, broken, etc

3.The machine spacing, height can be quickly adjusted, can adapt to different specifications of the bottle and cap

Technical Parameter:

1. Suitable specification: according to the sample provided by the customer

2. Place cap mode: manual cover placement

3. Capping form: servo clamping

4. Speed: 20-23 bottles / min

5. Program control: shared with filling machine

6. Conveyor belt: shared with filling machine

7. Capping motor: 400W servo motor

8. Overall power: about 0.6KW

9. Power supply: AC 220V, 50 / 60Hz, single phase

10. The frame is made of stainless steel

11. Air pressure: 0.6 ~ 0.8MPa